NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

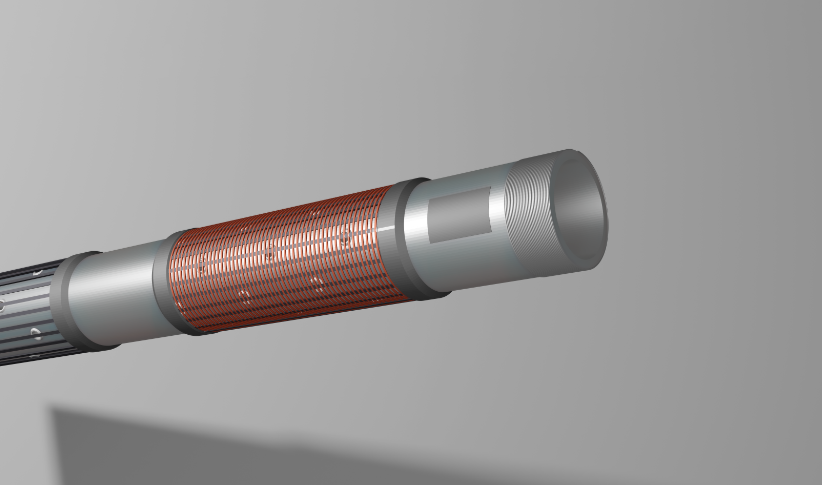

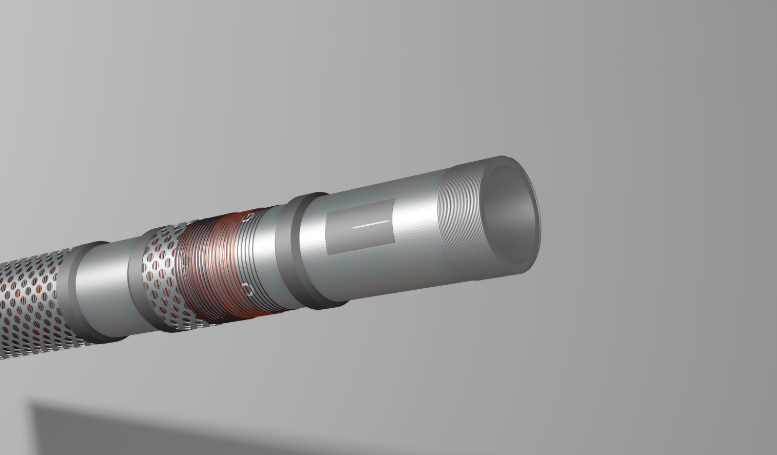

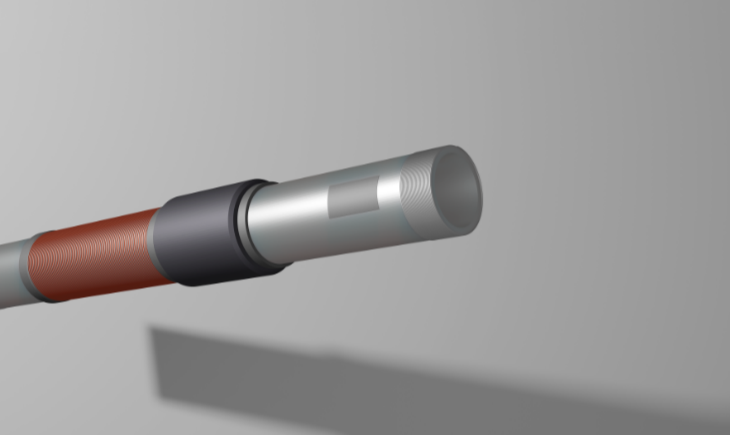

Downhole slotted filter FS-Shch - consists of a base perforated pipe and a filtering element made of a cylindrical slotted filter wound in a spiral from a wire of triangular cross-section

Closed slotted borehole filter FSZ-Shch - consists of a base perforated pipe and a filtering element made of a cylindrical slotted filter wound in a spiral from a wire of triangular cross-section. Sealing plugs are installed in the holes of the perforated pipe.

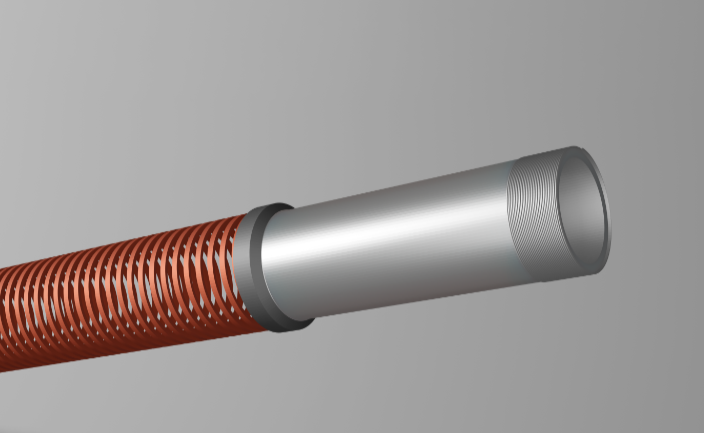

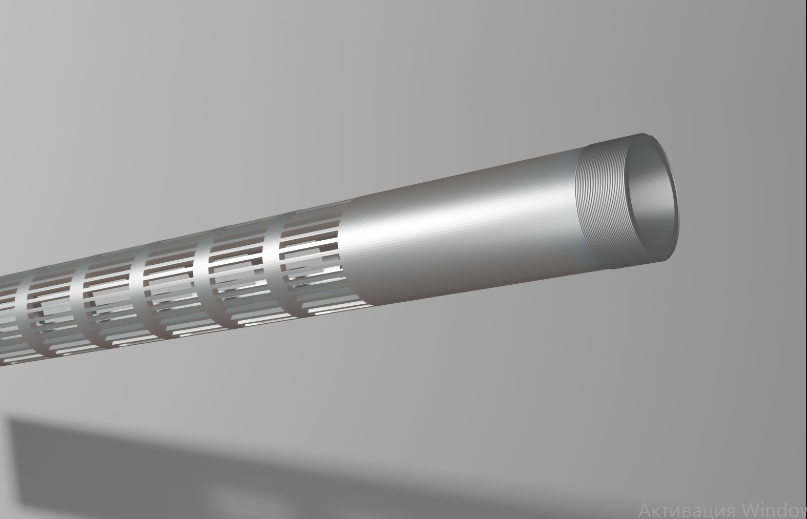

Borehole slotted frameless filter FSSH-B - consists of a filter element of a cylindrical slotted filter wound in a spiral from a wire of triangular or crosssection without a base pipe. The design feature of frameless slotted filters is a single filtering surface (no tubular frame), which eliminates the possibility of creating dead-end zones and significantly reduces hydraulic losses during fluid inflow into the well.

Well filters are installed as part of the production casing in the area of the productive formation of oil, gas and water wells of any design and operate in the environment of saline formation water, oil, natural gas, condensate and other well fluids. Filters are designed to filter the extracted product from inclusions, prevent the destruction of the bottomhole zone, remove sand and other mechanical impurities from wells, and also to reduce wear of pumping and compressor equipment and pipelines.

Well filters are installed as part of the production casing in the area of the productive formation of oil, gas and water wells of any design and operate in the environment of saline formation water, oil, natural gas, condensate and other well fluids. Filters are designed to filter the extracted product from inclusions, prevent the destruction of the bottomhole zone, remove sand and other mechanical impurities from wells, and also to reduce wear of pumping and compressor equipment and pipelines.

Well filters are installed as part of the production casing in the area of the productive formation of oil, gas and water wells of any design and operate in the environment of saline formation water, oil, natural gas, condensate and other well fluids. Filters are designed to filter the extracted product from inclusions, prevent the destruction of the bottomhole zone, remove sand and other mechanical impurities from wells, and also to reduce wear of pumping and compressor equipment and pipelines.

Well filters are installed as part of the production casing in the area of the productive formation of oil, gas and water wells of any design and operate in the environment of saline formation water, oil, natural gas, condensate and other well fluids. Filters are designed to filter the extracted product from inclusions, prevent the destruction of the bottomhole zone, remove sand and other mechanical impurities from wells, and also to reduce wear of pumping and compressor equipment and pipelines.

Downhole filter, which includes autonomous inflow control devices. The type and number of devices is selected in accordance with the well conditions, based on the simulation results. The use of such a construction allows:

- Align the inflow profile in the horizontal section of the wel l

- Restrict the flow of gas and water

- Extend the life of the well

- Align the inflow profile in the horizontal section of the wel l

- Restrict the flow of gas and water

- Extend the life of the well

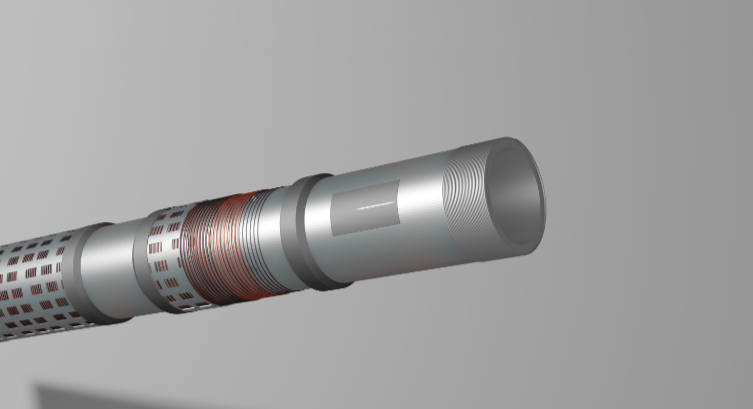

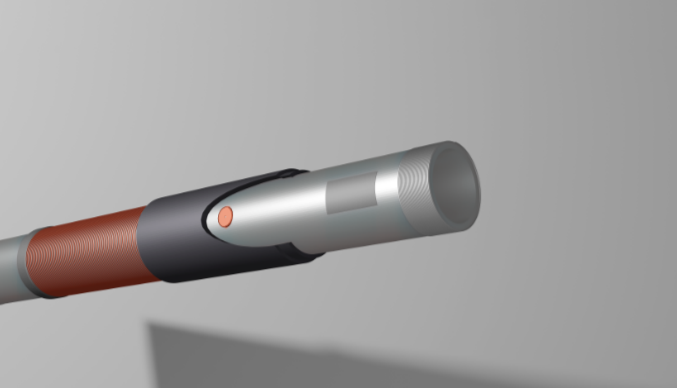

Downhole filter, which includes a sliding sleeve. The clutch is controlled to move the sleeve to the required position using a special tool that is lowered into the well. The use of such a construction allows:

- Control the inflow along the horizontal section of the well

- Eliminate gas and water breakouts

- Carry out acid treatment

- allows for technological flushing and multistage hydraulic fracturing during running

- Control the inflow along the horizontal section of the well

- Eliminate gas and water breakouts

- Carry out acid treatment

- allows for technological flushing and multistage hydraulic fracturing during running

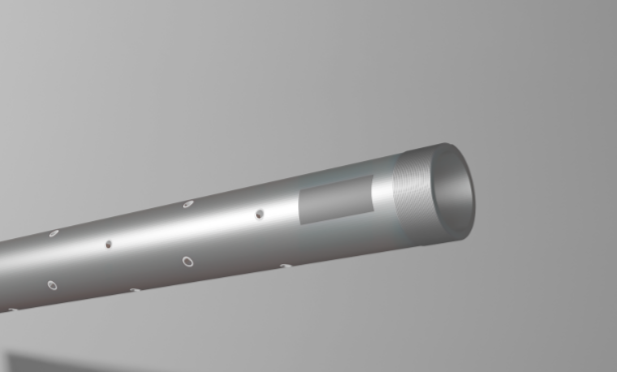

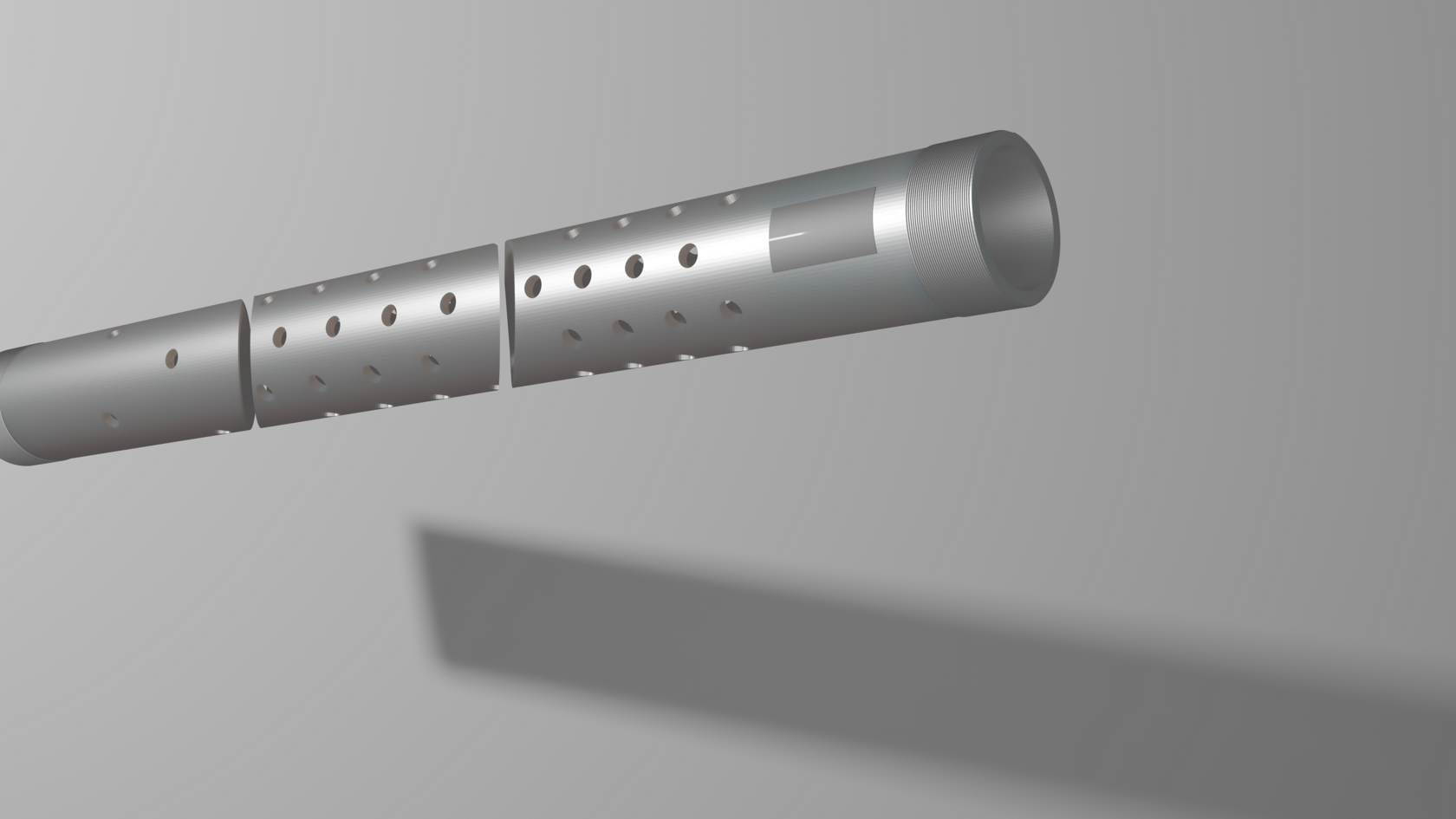

A set of filters for well completion with a pre-modeled number of holes, irregularly located along the entire length of the horizontal section. It is used to flatten the inflow profile along the entire length of the horizontal section, in order to reduce the risks of well flooding and, as a consequence, a higher oil production rate. When using variable perforation, filters are used with a different number of holes at the beginning and at the end of the liner, which positively affects the equalization of hydraulic resistance, thus the pressure in the tubular space is equalized along the entire length of the horizontal section of the well. This type of filter can be equipped with a filter element for sand protection.

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT

NEFTKOMPLEKT